VMetric

VMetric

VMetric - Spares Optimization

VMetric - Spares Optimization

VMetric® – free up to 50% of capital frozen in inventory while maintaining or improving performance levels!

VMetric® – free up to 50% of capital frozen in inventory while maintaining or improving performance levels!

Is your organization chronically short of the spare parts it needs to keep critical systems in operation while your warehouse bulges with stocks that never move? This all-too-common problem invariably stems from inadequate analysis of requirements, resulting from a lack of appropriate analytical tools. The solution seldom lies in costly, full-blown supply chain management solutions that take a long time to implement and have only a marginal effect at best.

Investment in spare parts should be expected to perform to the same standards as other investments.

The business case for acquisition or adjustment of a parts inventory should show that the proposed range and

distribution of parts minimizes the cost of achieving an operationally justified level of system performance.

Both the military and companies engaged in aerospace and defense business have long recognized the importance of using analytical models of sufficient power to determine optimal spare parts solutions for weapon systems. Other government bodies use such models too. Commercial use is less well advanced but growing, notably in aviation where airlines are finding they can maintain their accustomed service levels with inventory reductions of 40% to 50%.

The VMetric® family of spare parts optimization models leads the world in capability and flexibility. The VMetric optimizing engine was developed by Dr. Craig Sherbrooke, creator of the VARIMETRIC system used by the US Air Force. The models are unique in their abilities to deal with the complex interactions of multiple systems deployed at multiple operating locations. Different numbers and types of systems can be operated at multiple locations, and there is no limit to the number of parts and indenture levels in a given system. Operational availability targets can be global, system-specific or location-specific. The model can also run to a budget, a desired fill rate, an on-time departure rate, a lost production target, an average delay time target, the slope of the availability versus cost curve, a shortage cost target, or some combination of these and other measures of effectiveness. For example, VMetric is configured to address the special needs of urban mass transit, runs to a user-specified probability that the time interval between trains or buses will not exceed some target value (e.g. 8 minutes in rush hour). Advanced options include powerful demand analysis routines and built-in simulation features to enable testing of stock solutions in realistic scenarios.

VMetric addresses a wide variety of problems. The standard initial provisioning problem, starting with no stock, a performance goal and a limited budget is the most obvious. But you can also study periodic "top up" additions to existing stock, as well as geographic redistribution of existing or augmented stock. You can run the model in these different ways without changing the input data sets, simply by selecting the appropriate run-time options.

VMetric is available as a stand-alone tool, as a component of the TFD Logistician’s Work Station, and as the strategic planning element of the TFD Supply Chain Optimization system.

The VMetric Method

The VMetric Method

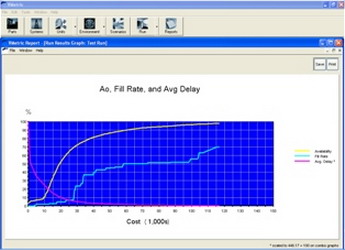

VMetric uses a multi-step marginal analysis

procedure, each iteration resulting in selection of the part and location that

yields, in light of earlier selections, the greatest reduction in expected

backorders per dollar, pound or cubic foot as the case may be. The procedure

takes into account: operational plans or schedules, expected part demand

patterns, lead times, buying and selling prices, existing stocks, minimum and

maximum stock constraints, assessed shortage costs, effects on the availability

of higher assemblies, criticality to system operation, opportunities for lateral

supply, and whether cannibalization of particular parts is permissible. The

output of marginal analysis is a set of cost-effectiveness curves of the kind

shown above. And since each point is the end of an optimal sequence of part

selections, a stock solution considered too costly can be adjusted, without

sacrificing optimality, simply by backtracking along any one of the curves until

further reduction in effectiveness becomes unacceptable. Along with recommended

stock levels the model reports EOQ values such as order quantities, reorder

points and a variety of other parameters commonly used in inventory management.

Connectivity. Through the TFD Database VMetric can share data with the MAAP®

Total Ownership Cost model and EDCAS®, the world standard for level of repair

and front-end analysis. TFD can also provide interface tools for extraction of

data from many sources – such as MIL-STD 1388-2B data exchange files, corporate

databases, spreadsheets, or LSAR 036 reports.